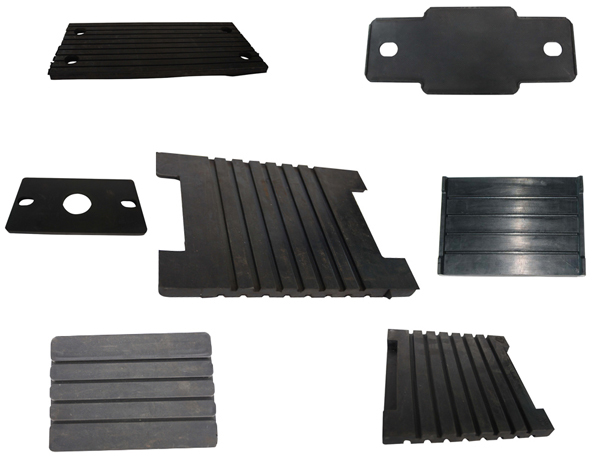

The rail pad laid under the rail is used to guarantee:

- The load distribution covering a larger surface area

- Reducing load concentration and usage fatigue stress

- Even contact area between the rail and supporting components

- Reducing noise and structural vibrations

- Sealing function between the top support and rail bottom

- Reducing rail wearing and relevant supporting components

Production Process of Rail Pads

Buckler Railway is equipped with rail pad production lines for 130sets of machines, for the whole process of injection, refining rubber, sulfuration, moulding and inspection, etc. We own the most engineers for rail pad development, design, production and inspection, with annual production capacity reaching up to 2000, 000 pieces. What’s more, rail pads for high speed rail lines are our featured products, including both the elastic rubber plates and height adjustment pads.

Rail pads for Normal Railways

A range of high-performance elastic rail pads have been developed for stiffness requirements and various application areas-from trams through standard gauge railways to heavy haul lines, this especially suitable for E-type rail fastening systems and SKL-type rail fastening system with material of HDPE/EVA/Rubber, the following parameters for reference.