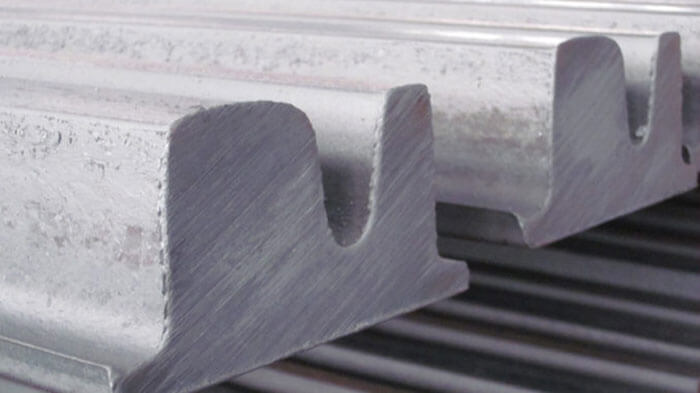

Technical Advantages of Block Rail

Superior road mixed traffic performance.

Due to the flange groove design on the block rails, the track and road pavement structure are well connected. The passing quality and speed of social vehicles are very good, thus improving the driving conditions of social vehicles.

The performance of the small-radius curve section of the block rail is superior.

The modern tram system adopts low floor vehicle operation, and the lines are mostly curved, with small turning radius, and the minimum radius is only 25m. The new block rail has good bending performance and can meet the higher requirements of rail performance in curve section. The block rails realize the integration of the anti-dropping guard rail and has good wear resistance.

The block rail is low in height, light in weight and cost saving.

Because the structure of the rail web is removed, the center of gravity of the block rail is lowered, and the mass is also reduced a lot. From the aspect of material cost, redundant steel consumption is greatly reduced, and the economic benefits are significant.

Types of Block Rails

Our block rails are produced in accordance with the EN14811 standard and meet the quality standards stipulated by the EN14811 standard. There are mainly three kinds of block rails: 53k2, 57k2 and 58k2, and the main difference is reflected in the size of groove width. Block rail products can also be customized according to customer drawings.

Block Rail VS LR55 Tram Track VS Bridge Rail

LR55 tram track is also a type of tram track, its structure is similar to that of a block track. The difference between LR55 track and other tram tracks is that the LR55 track is directly slotted on the ground, and then the track is fixed in the groove. This laying method has obvious advantages and will not affect the pipeline network structure below the surface.

Only from the structural point of view, there is another inverted U-shaped railway similar to the block rail structure, called the bridge rail. This kind of bridge rail has a simple structure and was used on an early 7 ft 1⁄4 in railroad.