The Classification and Structure of Rail Frog

The rail frog can be divided into a straight frog and a curved frog according to the plane type, and it also can be divided into a fixed frog and a movable point frog (swingnose crossing) by structure type.

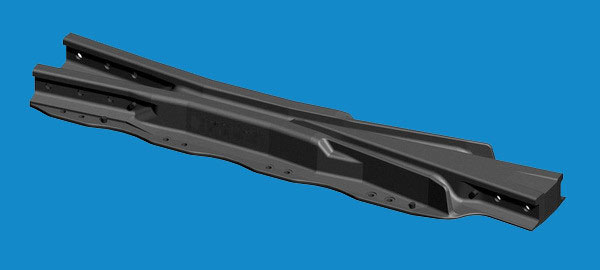

Fixed frog

Rail bound manganese frog (RBM rail frog)

Rail bound manganese frog (RBM rail frog) is a kind of one-piece cast frog with manganese steel. Because the simultaneous casting of the crossing nose and the wing rail, the rail bound manganese frog’s integrity and stability are better. High manganese steel is a kind of alloy steel with both high contents of manganese and carbon (manganese 12.5%, carbon 1.2%). The railway frog cast with high manganese steel has higher strength and good wear resistance. Therefore, the rail bound manganese frog has a longer service life and more convenient maintenance.

Combined type rail frog:

The combined type rail frog is made up of the crossing nose, the wing rail and other parts. The railway frog of this structure is easy to use. Due to it has no special process requirements, so the process and manufacture technology is not complicated. Because of the assembled structure, the combined type rail frog has more separate parts and need more maintenance work.

Movable point frog (swingnose crossing)

The movable point frog refers to a railroad frog structure with movable parts. Because the railway frog is partially movable, the harmful space created on the fixed frog is eliminated and making the train runs smoothly. The movable point frog has three types, they are crossing nose movable type, wing rail movable type and other movable railway frogs.

- Crossing nose movable type

The crossing nose is movable and the wing rail is fixed. When the train changes its orbit through the rail switch, railroad frog guides the train into the correct track through the movement of crossing nose. This type of rail frog has the advantage of good lateral stability and will not cause the train to derail due to the wrong track. Its disadvantage is that the rail frog is relatively long and complicated to manufacture. - Wing rail movable type

This kind of rail frog structure has fixed crossing nose and movable wing rail. It can be divided into two types: one-sided wing rail movable and two-sided wing rail movable. Movable point frog can effectively improve the speed of the train passing through the rail turnout, which is widely used in high-speed railway lines. The movable wing rail frog has poor lateral stability compared to the crossing nose type frog, and the structure of the fixing device is relatively complicated. - Other movable railway frogs

For example, Germany’s UIC60 rail switch uses a sliding block to fill the frog flange groove to make the train change the running track. Another example, the flexible movable point frog turnout and movable point frog rail speed-raising turnout have been developed in China. This movable point frog rail speed-raising turnout can be used in cross-regional seamless rail lines. The straight speed of the line laying this kind of rail frog turnout can reach 160 km/h.

Railroad Frog Dimensions

Important factors affecting railway frog selection

- As an important part of the rail switch, the selection of the railway frog needs to be based on the type and size of the rail turnout, and sometimes it needs to be matched with turnout in railway.

- Different railroad frog is needed according to the curvature radius of intersecting railway. The greater the curvature radius of the turning railway is, the larger number of the railway frog used will be, and the less angle of the rail frog will be. At the same time, the higher speed of the locomotive which is allowed to pass the rail switch, the higher smoothness of the train.

- The number of railroad frogs required will vary depending on the number of bifurcated railways. In general, the number of rail frogs required for a single turnout (lateral turnout) in railway is one.

- According to the actual situation such as the terrain (slope) of the railway laying, special railroad frogs that meet the requirements will be customized. Therefore, we often receive customized requirements from customers and make the frog according to their drawings.

- The railway frog is also required to be selected for the different types of locomotives crossing the rail switch. Electric locomotives, mine cars, ordinary trains, high-speed trains, these trains have different loads, need to change the track at different speeds, so the choice of rail turnout frog also needs to be different.

Hook Twin Tie Plates Used on Railway Frog

It is a special shape of the rail tie plate, which is specially used for the special size of the rail frog part and the guard rail of the rail turnout. The hook twin tie plate is usually used in pairs and fixed with fasteners such as screw spike or rail frog bolt.

What’re the Advantages of Railway Frog Produced by Buckler Railway

Using new materials

We use new high manganese steel to make the railroad frog. This new material is obtained by re-alloying high manganese steel with elements such as copper, vanadium and titanium, etc. The self-lubrication performance of the high manganese steel frog has been improved with the addition of new elements, thus reducing the friction force between the wheel and rail and improving the service life of the rail frog.

Avoiding rail track irregularity

The irregularity of high-speed switch frog area has always been a difficult problem in the field of railway safety production. In order to reduce the incidence of irregularities on turnout in railway, the vertical tip hid structure or horizontal tip hid structure are adopted in our railway frogs, which can effectively reduce wheel-rail contact irregularities.

Well-made railway frogs

All our railroad frog products are created in accordance with the mold standards. For customized frog products, our engineers will strictly follow the drawing data and carry out multiple product trials until the customer requirements are met. We only make well-made railway frog. Welcome to send inquiry for more details about railway frog.