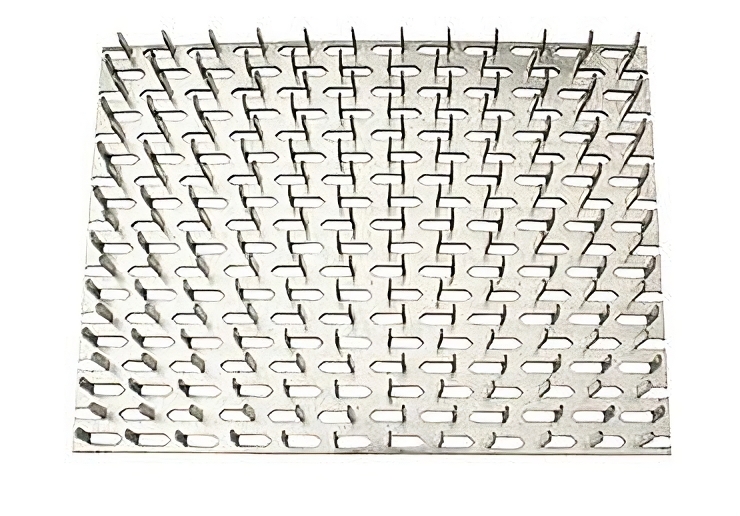

Materials: DX51D-Z275/G300-Z275

Materials: DX51D-Z275/G300-Z275

Coating: Zine

Usage: wooden sleepers, wooden construction

Shape: Round, square, or customized

Thickness:0.8-1.8mm

Strandard: Both standard and customized sizes are available

Hazards of Wooden Sleeper Cracking

The service life of railway sleepers can reach about 15 years after oil injection and anti-corrosion treatment. Because wooden sleepers are exposed to the external environment for a long time, the degree of environmental dryness and wetness is uncontrollable, resulting in the unstable moisture content of the wood, which will cause a certain degree of cracking. If it is crushed by an overloaded train, or the force is uneven, it will also aggravate the cracking of the railway sleepers.

Severe cracking of the wooden sleeper will cause the rails erected on it to lose support, resulting in collapse. From the slightest, the train operation is blocked, and at the worst, it will cause the train derailment accident and endanger the safety of life and property. The problem of wooden sleeper cracking seems to be very small, but in fact, it is not paid attention to, and the harm is very serious.

The gang nail is nailed to the end of the wooden sleeper. When the gang nail is pressed into the sleeper, all the nails gather the fibers of the wood together like a “claw”. The pressure between adjacent nails also reduces the tendency of splitting, thereby slowing down the cracking process of the wooden sleepers.

Manufacturing Process and Application of Gang Nail

A gang nail plate is a kind of light metal plate, sometimes also known as mending plate, or nail plate. It is made of light gauge galvanized steel by cold forming. There are holes all over the gang nail plate with nail teeth on one side. The gang nail plate is embedded in the wood by a hydraulic press or roller tool to connect different trusses or fix the end of the wooden sleeper.

The gang nail plate is made of high-quality structural steel such as ASTM A635/A635M, A591, A792/A792M, A167, and is protected by coatings such as zinc, zinc-aluminum combined gold and stainless steel. The company can design and manufacture gang nail plates with different lengths, widths, and thicknesses according to customer needs.