Crane traveling track is the running route of the crane laying by the crane rails. It can ensure the crane running along the prescribed line and ensure transportation safety. The selection of crane rail is usually matched according to the type of crane. Specifically, we mainly refer to the maximum wheel pressure and minimum wheel pressure of the crane to calculate the crane rail size and selected wheel size by the crane.

According to different types of cranes, there are different supporting crane rail, such as overhead crane rail, gantry crane rail, etc. When we choose the crane rail, we should not only consider the size of the wheel, but also consider the design and installation of the crane rail in the actual environment. Here are some tips you should pay attention to when choosing the crane rail.

- Crane rail design and installations

- Crane rail type and size selection

- Crane rail suppliers selection

Chinese standard crane rail

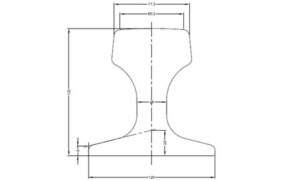

A65 crane rail specification

Rail Designation: A65

Rail Origin: Germany

Standard: DIN 536

Area of section: 5514 mm2

Calculated Mass: 43.1 kg/m

Neutral Axis to base: 30.4 mm

JISE standard crane rail

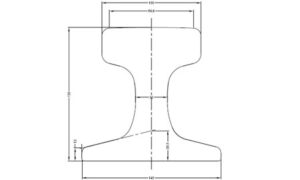

CR 73KG crane rail specification

Rail Designation: CR 73KG

Rail Origin: Japan

Standard: JISE 1103/1101

Area of section: 9361 mm2

Calculated Mass: 73.3 kg/m

Neutral Axis to base: 67 mm

UIC standard crane rail

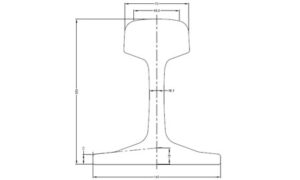

UIC 54 crane rail specification

Rail Designation: UIC 54

Rail Origin: International

Standard: UIC 860

Area of section: 6974 mm2

Calculated Mass: 54.4 kg/m

Neutral Axis to base: 75.1 mm

Other standard crane rail

- ASCE crane rail, ARAB crane rail and AREA crane rail

- IS (ISCR) standard crane rail

- Other DIN standard crane rail (A45, A55, A150 crane rail)

Crane rail successful cases

1. US Gulf crane project uses QU80 crane rails.

2. Philippines industrial plant crane rail project uses 60E1 crane rails.

Crane Rail Clips

Crane rail clips are used to hold the crane rail and make it fixed on the crane soleplate. The crane rail clip is an important crane rail fastener. The upper part of crane rail clips is pressed on the crane rail and the lower part is fixed on the crane sloe plates. There are two ways to fix the crane rail clips, one is fixed by rail bolt, the other is fixed by welding. Each of the ways has its advantages and suited to different situations.

Bolted type crane rail clips

Bolted type crane rail clip and bolt should be used together. Due to the large load, high strength bolts are usually used instead of ordinary bolts. Different high strength bolts (ASTM A325 Bolts,astm a193, a307 bolt, a490 bolts, etc.) should be selected for reinforcement according to different loads.

- Feature: suitable for light crane, convenient installation and maintenance

- Dimensions: 3112, 3116, 3120, 3124, 3224

- Suitable crane rail pad: Mk2, Mk7

- Applicable crane rails: A65, A100, A120, JIS37, JIS50, JIS60, QU80, QU70, QU120, UIC54, UIC60 etc.

Welded type crane rail clips

The welded type crane rail clip has two parts, the lower part is welded on the crane sole plate, the upper part is fixed the crane rail and connected to the lower part by track bolt. Because using the welding method, the crane rail clips can bear more forces from transverse displacement. Therefore, the crane rail clips can be used for the crane with higher load capacity, common in the field of heavy industry.

- Feature: suitable for heavy load crane

- professional welding technique is required for installation

- Dimensions: 1116, 1216, 9116, 9120, 9124, 9220

- Suitable crane rail pad: Mk2, Mk7

- Applicable crane rails: A65, A100, A120, JIS37, JIS50, JIS60, QU80, QU70, QU120, UIC54, UIC60 etc.

Crane rail clips successful cases

1. Thailand crane rail project uses 1216 crane rail clips.

2. Seychelles shipyard crane rail track project uses type 9120/15/38 crane rail clips

Crane Rail Clamp

There is a special kind of crane rail clip called crane rail clamp. We have rail clamps for cranes popular with customers used with GB standard crane rails.

Crane Sole Plates

The crane sole plate is a crane rail accessory that is placed under the crane rail to support and disperse the pressure carried by the crane. According to the different requirements of the crane load, the crane sole plates can be divided into individual type and continuous type.

Individual type crane sole plates

For the light-duty crane, the individual type crane sole plates can completely support the pressure from the crane wheel. Individual type crane sole plate is a very economical choice when the crane track does not require full force. Individual type crane soleplates are easy to install without special customization and saving installation time.

Continuous type crane sole plates

Continuous type crane sole plate has a good supporting function for the crane rails which need a continuous force in the whole track. Due to the large load, heavy cranes generally require continuous multiple-point force, and continuous type crane sole plates can give higher safety factor support. Based on safety guarantees, the manufacture of continuous type crane sole plates needs to be made based on actual crane rail track groove data.

Crane Rail Pad

Crane rail pad is an important component used between crane sole plate and crane rail to buffer and disperse the load pressure from the crane. According to different crane soleplates, different types of crane rail pads need to be selected.

Individual type crane rail pad

Individual type crane rail pad need to be used together with Individual type crane sole plate. The crane rail pad is flexible and can disperse pressure very well.

Continuous type crane rail pad

This type of crane rail pad is continuous and uninterrupted, laid on the continuous sole plate. The continuous type crane rail pads make the pressure from high load crane more evenly distributed.

Crane rail pad successful case

Malaysia Ann Joo Resources Berhad crane rail project uses 43KG crane rails and 6A-4 crane rail pads. It has been used safely for two years.